Next-Generation Pyrolysis Technology for a Sustainable Future

YSR’s cutting-edge pyrolysis systems transform waste into valuable resources with industry-leading efficiency and environmental responsibility.

- Pyrolysis Oil – a valuable alternative fuel or chemical feedstock

- Carbon Black – for rubber, plastics, and industrial applications

- Syngas – reused for plant energy or captured for industrial use

- Recovered Metals – cleanly separated for resale or recycling

Key advantages of YSR technology:

- Automated, low-maintenance operation

- Minimal emissions meeting global environmental standards

- Energy self-sufficiency through integrated syngas recovery

- Modular, scalable design adaptable to a range of project sizes

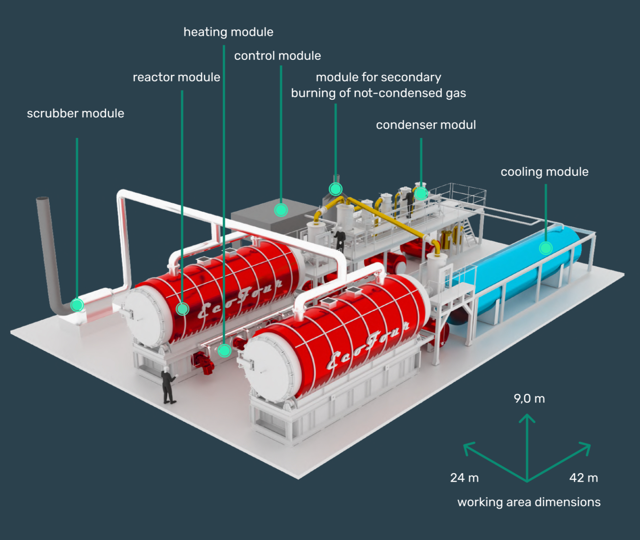

Modular and Compact Pyrolysis Plants for Every Business Need

Modular Pyrolysis Plant (18 t/day)

Designed for industrial-scale operations, our 18-ton per day plant delivers unmatched efficiency and profitability. Featuring robust engineering, automated operation, and superior yields, it’s the ideal choice for companies ready to lead the recycling revolution.

- High-capacity output

- Fully automated and easy to operate

- Rapid ROI and reduced operational costs

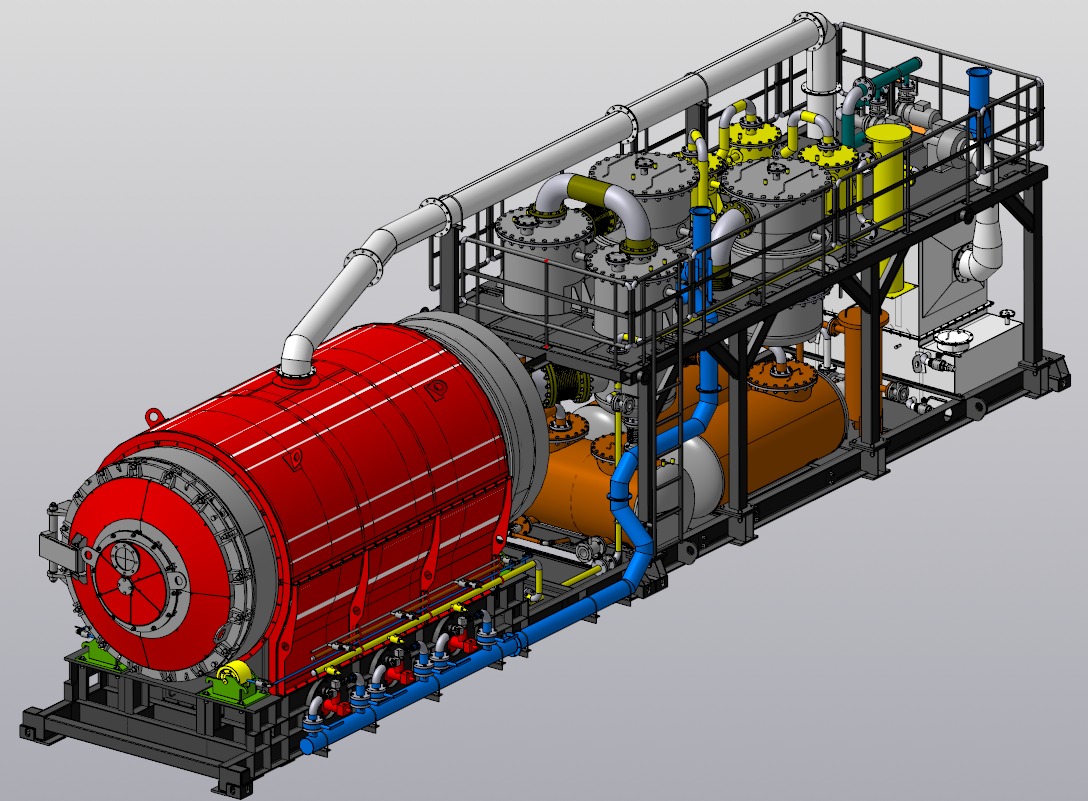

Compact Pyrolysis Plant (4 t/day)

Ideal for decentralized projects or smaller operations, our 4-ton plant offers the same innovative technology in a compact, modular format. Enjoy faster installation, lower startup investment, and full scalability without compromising on output quality.

- Transportable and space-efficient

- Fast setup and commissioning

- Scalable for growing businesses

Products & Output

Unlock New Revenue Streams with YSR Pyrolysis Solutions

YSR plants can process a wide variety of waste streams, including:

- Waste tires (ELT - End-of-Life Tires)

- Post-consumer plastics (PP, PE, PS)

- Industrial and mixed plastic waste

End Products:

- Pyrolysis oil for marine fuel and industrial use

- Carbon black for rubber and manufacturing industries

- Syngas for onsite energy production

Our high-purity products open profitable opportunities in the marine fuel, chemical, and rubber manufacturing sectors.

Why YSR? Maximizing Profitability While Minimizing Environmental Impact

- Fast Return on Investment: Typical payback within 2–3 years.

- Operational Savings: Significant reductions in waste disposal and landfill costs.

- Environmental Leadership: Low-emission, energy self-sufficient plants boost your ESG credentials.

- Market Access: Produce high-quality commodities in demand across multiple industries.

Certified Excellence, Patented Innovation

YSR’s technology is backed by internationally recognized certifications for quality and environmental compliance and proprietary innovations in modular design and energy recovery systems.

YSR – Pioneering Sustainable Waste Management Solutions

At YSR, we believe in a cleaner, more profitable future. Combining decades of engineering expertise with a commitment to sustainability, we deliver world-class modular pyrolysis systems tailored to the evolving needs of industry and the environment.

Our Mission:

To revolutionize waste management by turning environmental challenges into economic opportunities.

Our Promise:

Innovative solutions, dependable service, and lasting partnerships.

Get in Touch with YSR

We’re ready to support your waste recycling ambitions. Contact us today for more information or a customized proposal.